US20080230196A1 - Softening compositions for treating tissues which retain high rate of absorbency - Google Patents

Softening compositions for treating tissues which retain high rate of absorbency Download PDFInfo

- Publication number

- US20080230196A1 US20080230196A1 US11/726,588 US72658807A US2008230196A1 US 20080230196 A1 US20080230196 A1 US 20080230196A1 US 72658807 A US72658807 A US 72658807A US 2008230196 A1 US2008230196 A1 US 2008230196A1

- Authority

- US

- United States

- Prior art keywords

- weight percent

- tissue

- composition

- amount

- glycerin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 0 *[Si]([1*])([1*])OC([1*])([1*])CC([1*])([2*])CC([1*])([3*])C[Si]([1*])([1*])B Chemical compound *[Si]([1*])([1*])OC([1*])([1*])CC([1*])([2*])CC([1*])([3*])C[Si]([1*])([1*])B 0.000 description 2

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L83/00—Compositions of macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon only; Compositions of derivatives of such polymers

- C08L83/04—Polysiloxanes

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

- D21H19/20—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

- D21H19/24—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D21H19/32—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds obtained by reactions forming a linkage containing silicon in the main chain of the macromolecule

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/80—Paper comprising more than one coating

- D21H19/82—Paper comprising more than one coating superposed

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/80—Paper comprising more than one coating

- D21H19/82—Paper comprising more than one coating superposed

- D21H19/824—Paper comprising more than one coating superposed two superposed coatings, both being non-pigmented

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/14—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by function or properties in or on the paper

- D21H21/22—Agents rendering paper porous, absorbent or bulky

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/002—Tissue paper; Absorbent paper

- D21H27/004—Tissue paper; Absorbent paper characterised by specific parameters

- D21H27/005—Tissue paper; Absorbent paper characterised by specific parameters relating to physical or mechanical properties, e.g. tensile strength, stretch, softness

Definitions

- polysiloxanes for treating tissues is well known in the tissue industry.

- Polysiloxanes provide surface softness by providing a slick feel to the tissue.

- polysiloxanes are relatively water repellant, such that the rate of absorbency for the treated tissue is lessened.

- polysiloxanes are relatively expensive. Consequently there is a continual need for improved tissue softening compositions that not only provide softness, but retain a satisfactory absorbent rate and are cost effective.

- Tissue softening compositions have been discovered which cost effectively provide softness while retaining a good absorbent rate (as measured by the Wet Out Time test, hereinafter described).

- the invention resides in a softening composition particularly useful for topically treating tissues, the composition comprising a polysiloxane, a fatty alkyl derivative and glycerin.

- these three ingredients are sometimes referred to as “actives”.

- Optional ingredients include formulation aids and/or skin beneficial agents.

- the softening composition can contain, based on the total amount of actives in the composition, from about 5 to about 40 weight percent polysiloxane, from about 10 to about 50 weight percent of a fatty alkyl derivative, from about 20 to about 80 weight percent glycerin, and from 0 to about 10 weight percent formulation aids and/or skin beneficial agents.

- the invention resides in a tissue sheet containing a topically applied softening composition, said softening composition comprising, based on the total amount of actives in the composition, from about 5 to about 40 weight percent polysiloxane, from about 10 to about 50 weight percent of a fatty alkyl derivative, from about 20 to about 80 weight percent glycerin and from 0 to about 10 weight percent formulation aids and/or skin beneficial agents.

- the invention resides in a tissue sheet containing a topically applied softening composition, said softening composition comprising, on a weight percent basis, from about 20 to about 30 weight percent polysiloxane and from about 20 to about 40 weight percent glycerin. More specifically, the weight ratio of polysiloxane:glycerin can be from about 0.5 to about 1.4.

- the amount of the softening composition actives in the tissue can be, based on the dry weight of the tissue, from about 0.2 to about 20 weight percent, more specifically from about 0.2 to about 10 weight percent, more specifically from about 0.5 to about 5 weight percent, and still more specifically from about 1 to about 3 weight percent.

- the softening composition can be applied to the tissue sheet in the form of a neat blend, an aqueous solution or an aqueous emulsion.

- concentration of the softening composition in the aqueous solution or aqueous emulsion can be from about 35 to about 80 weight percent, more specifically from about 40 to about 70 weight percent and still more specifically from about 45 to about 70 weight percent.

- Suitable methods of applying the softening composition to the sheet, either directly or indirectly, include printing or spraying.

- the Wet Out Time for tissue sheets treated with the softening compositions of this invention can be about 20 seconds or less, more specifically about 15 seconds or less, more specifically from about 3 to about 15 seconds and still more specifically from about 3 to about 10 seconds.

- the amount of polysiloxane in the softening composition can be from about 5 to about 40 weight percent, more specifically from about 5 to about 30 weight percent and still more specifically from about 5 to about 20 weight percent.

- Polysiloxanes useful for purposes of this invention can have one or more pendant functional groups such as amine, quaternium, aldehyde, epoxy, hydroxy, alkoxyl, polyether and carboxylic acid and its derivatives, such as amides and esters.

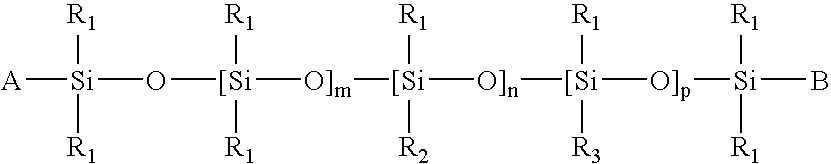

- Particularly suitable polysiloxanes have the following general structure:

- R 4 and R 5 are independently a C 2 to C 8 alkylene diradical, which can be straight chain or branched, substituted, or unsubstituted;

- X is an oxygen or N—R 8 ;

- R 6 , R 7 and R 8 are independently hydrogen, a substituted or unsubstituted C 1 or C 2 , a substituted or unsubstituted straight chain or branched or cyclic C 3 to C 20 alky radical, or an acyl radical, such as an acetyl radical; and

- R 3 is of the structure: R 9 —Y—[C 2 H 4 O] r —[C 3 H 6 O] q —R 10

- Y is an oxygen or N—R 11 ;

- R 9 is a C 2 to C 8 alkylene diradical, which can be straight chain or branched, substituted or unsubstituted;

- R 10 and R 11 are independently hydrogen, a substituted or unsubstituted C 1 or C 2 , a substituted or unsubstituted, straight chain or branched or cyclic C 3 to C 20 alkyl radical;

- r is from 1 to 100,000

- R 2 ⁇ R 1 can also be a nitrogen quarternium.

- Suitable commercially available polysiloxanes include AF-2340, AF-2130, AF-23, HAF-1130, EAF-3000, EAF-340, EAF-15, AF-2740, WR-1100, WR-1300 and Wetsoft CTW from Kelmar/Wacker; DC-8822, DC-8566, DC-8211, DC-SF8417, DC-2-8630, DC-NSF, DC-8413, DC-SSF, DC-8166 from Dow Corning; SF-69, SF-99 SF-1023 from GE Silicones and Tegopren 6924, Tegopren 7990, Tego IS4111 from Goldschmidt/Degussa.

- the amount of fatty alkyl derivative in the softening composition can be from about 10 to about 50 weight percent, more specifically from about 20 to about 50 weight percent and still more specifically from about 30 to about 50 weight percent.

- Fatty alkyl derivatives particularly suitable for purposes of this invention can have the following general structure:

- R 14 is a C 8 to C 40 alkyl radical, which can be substituted or unsubstituted, primary, secondary or tertiary; straight chain, branched or cyclic; and

- G is hydroxy, amine, sulfonate, sulfate, phosphate, acid or acid derivative, or -Q-[C 2 H 4 O ] l —[C 3 H 6 O] j —[C t H 2t O] v —R 13 radical;

- Q is an oxygen radical, an NH radical or N—[C 2 H 4 O ⁇ l —[C 3 H 6 O] j —[C t H 2t O] v —R 13 radical;

- R 13 is a hydrogen, a substituted or unsubstituted C 1 to C 6 alkyl radical, a straight chain or branched C 1 to C 6 alkyl radical, or a cyclic C 1 to C 6 alkyl radical;

- i is independently from 0 to 100,000, where the oxide moieties are distributed along the polymer backbone randomly or as blocks;

- Suitable fatty alkyl derivatives are 9-EO ethoxylated tridecylalcohol; Ceteth-10; Ceteth-12 (12-EO ethoxylated cetyl alcohol); Ceteth-20; Pluraface A-38, Macol CSA 20 and Macol LA 12 from BASF; Armeen 16D, Armeen 18D, Armeen HTD, Armeen 2C, Armeen M2HT, Armeeh 380, Ethomeen 18/15 Armid O, Witconate 90, Witconate AOK, and Witcolate C from Akzo Nobel and Tergitol 15-S-9, Tergitol 15-S-7, Tergitol 15-S-12, Tergitol TMN-6, Tergitol TMN-10, Tergitol XH, Tergitol XDLW, and Tergitol RW-50 from Dow Chemical.

- the amount of glycerin in the softening composition can be, based on the total amount of actives in the composition, from about 20 to about 80 weight percent, more specifically from about 25 to about 80 weight percent, more specifically from about 30 to about 80 weight percent and still more specifically from about 40 to about 70 weight percent.

- Suitable formulation aids include, without limitation, emulsifiers, co-solvent, anti-foaming agents and preservatives.

- Suitable skin beneficial agents include, without limitation, aloe, vitamin-E, chamomile and ⁇ -hydroxy acids.

- the “Wet Out Time” of a tissue sheet treated in accordance with the present invention is determined by cutting 20 sheets of the tissue sheet sample into 2.5 inch squares.

- the number of sheets of the tissue sheet sample used in the test is independent of the number of plies per sheet of the tissue sheet sample.

- the 20 square sheets of the tissue sheet sample are stacked together and stapled at each corner to form a pad of the tissue sheet sample.

- the pad of the tissue sheet sample is held close to the surface of a constant temperature distilled water bath (23° C. ⁇ 2° C.), which is the appropriate size and depth to ensure the saturated pad of the tissue sheet sample does not contact the bottom of the water bath container and the top surface of the distilled water of the water bath at the same time, and dropped flat onto the surface of the distilled water, with staple points on the pad of the tissue sheet sample facing down.

- the time necessary for the pad of the tissue sheet sample to become completely saturated, measured in seconds, is the Wet Out Time for the tissue sheet sample and represents the absorbent rate of the tissue sheet sample. Increases in the Wet Out Time represent a decrease in absorbent rate of the tissue sheet sample.

- tissue means a paper sheet having a bulk of about 2 cm 3 or greater/ gram, more specifically about 2.5 cm 3 or greater/ gram and still more specifically about 3 cm 3 or greater/gram. Such sheets are particularly useful for facial tissue, bath tissue and paper towels and can be made by any method well known to those skilled in the tissue arts.

- the bulk is calculated as the quotient of the caliper (hereinafter defined), expressed in microns, divided by the basis weight, expressed in grams per square meter. The resulting bulk is expressed as cubic centimeters per gram.

- caliper is the thickness of a single tissue sheet, and may either be measured as the thickness of a single tissue sheet or as the thickness of a stack of ten tissue sheets and dividing the ten tissue sheet thickness by ten, where each sheet within the stack is placed with the same side up. Caliper is expressed in microns and can be measured in accordance with TAPPI test methods T402 “Standard Conditioning and Testing Atmosphere For Paper, Board, Pulp Handsheets and Related Products” and T411 om-89 “Thickness (caliper) of Paper, Paperboard, and Combined Board” optionally with Note 3 for stacked tissue sheets.

- the micrometer used for carrying out T411 om-89 is a Bulk Micrometer (TMI Model 49-72-00, Amityville, N.Y.) or equivalent having an anvil diameter of 4 1/16 inches (103.2 millimeters) and an anvil pressure of 220 grams/square inch (3.3 g kilo Pascals).

- dry weight percent in reference to a composition or tissue sheet containing a composition means that the amount of free water or other volatile components in the composition or tissue product are ignored. Stated differently, the “dry” weight percent is intended to represent the amount of “active components” in the composition. Therefore, for tissue sheets, all recited dry weight percent amounts refer to tissue sheets that have been aged for at least three (3) weeks and therefore have equilibrated with ambient conditions. The dry weight percent amounts can be determined by chemical extraction and analysis of the extract or, if the conditioned basis weight of the tissue sheet prior to treatment is known, by subtracting the conditioned basis weight of the untreated tissue from the conditioned basis weight of the treated tissue and dividing the difference by the conditioned basis weight of the treated tissue and multiplying by 100.

- the “geometric mean tensile strength” is the square root of the product of the dry machine direction tensile strength multiplied by the dry cross-machine direction tensile strength and is expressed as grams per 3 inches of sample width.

- the machine direction tensile strength is the peak load per 3 inches of sample width when a sample is pulled to rupture in the machine direction.

- the cross-machine direction (CD) tensile strength is the peak load per 3 inches of sample width when a sample is pulled to rupture in the cross-machine direction.

- samples for tensile strength testing are prepared by cutting a 3 inches (76.2 mm) wide by 5 inches (127 mm) long strip in either the machine direction (MD) or cross-machine direction (CD) orientation using a JDC Precision Sample Cutter (Thwing-Albert Instrument Company, Philadelphia, Pa., Model No. JDC 3-10, Serial No. 37333).

- the instrument used for measuring tensile strengths is an MTS Systems Sintech 11S, Serial No. 6233.

- the data acquisition software is MTS TestWorks® for Windows Ver. 3.10 (MTS Systems Corp., Research Triangle Park, N.C.).

- the load cell is selected from either a 50 Newton or 100 Newton maximum, depending on the strength of the sample being tested, such that the majority of peak load values fall between 10-90% of the load cell's full scale value.

- the gauge length between jaws is 4 ⁇ 0.04 inches (101.6 ⁇ 1 mm).

- the jaws are operated using pneumatic-action and are rubber coated.

- the minimum grip face width is 3 inches (76.2 mm), and the approximate height of a jaw is 0.5 inches (12.7 mm).

- the crosshead speed is 10 ⁇ 0.4 inches/min (254 ⁇ 1 mm/min), and the break sensitivity is set at 65%.

- the sample is placed in the jaws of the instrument, centered both vertically and horizontally. The test is then started and ends when the specimen breaks.

- the peak load is recorded as either the “MD tensile strength” or the “CD tensile strength” of the specimen depending on direction of the sample being tested. At least six (6) representative specimens are tested for each product or sheet, taken “as is”, and the arithmetic average of all individual specimen tests is either the MD or CD tensile strength for the product or sheet.

- the geometric mean tensile strength of the products of this invention can be, without limitation, from about 600 to about 1200 grams per 3 inches, more particularly from about 700 to about 1000 grams per 3 inches and still more specifically from about 700 to about 900 grams per 3 inches.

- any ranges of values set forth in this specification are to be construed as written description support for claims reciting any sub-ranges having endpoints which are whole number values within the specified range in question.

- a disclosure in this specification of a range of from 1 to 5 shall be considered to support claims to any of the following sub-ranges: 1-4; 1-3; 1-2; 2-5; 2-4; 2-3; 3-5; 3-4 and 4-5.

- FIG. 1 is a plot of the results of Example 1 from Table 2, illustrating the softness as a function of the glycerin percentage in the formulation containing polysiloxane and glycerin. As shown, softness peaks at about 35 weight percent glycerin and then falls off significantly as the percentage of glycerin is increased.

- FIG. 2 is a plot of the results of Example 3 from Table 6, illustrating the softness as a function of strength for various glycerin amounts in the formulation containing polysiloxane, fatty alkyl derivative and glycerin. As shown, softness peaks at about 33 weight percent glycerin.

- tissue basesheets for use in accordance with this invention were either wet-pressed creped tissue sheets or uncreped throughdried tissue sheets.

- the wet-pressed tissue sheets were converted into three-ply facial tissue treated products and the uncreped throughdried tissue sheets were converted into single-ply bath tissue treated products for testing. After the tissue products were made, they were tested for geometric mean tensile strength, wettability (Wet Out Time, described above) and softness.

- the tissue sheets were made as described below.

- these tissue basesheets were produced using a conventional wet-pressed tissue making process well known in the art. More particularly, an aqueous suspension of papermaking fibers was issued from a layered headbox onto a forming fabric.

- the furnish consisted of 70 weight percent hardwood (eucalyptus) fibers and 30 weight percent softwood fibers.

- a vacuum box beneath forming fabric was adapted to remove water from the fiber furnish to assist in forming a web.

- the newly formed web was transferred to a felt with aid of a pick up roll. While supported by the felt, the tissue web was lightly pressed onto the surface of a Yankee dryer using a press roll. The dried web was creped from the surface of the Yankee dryer and the resulting single-ply tissue basesheet was wound onto a parent roll. Thereafter, the basesheets from three like parent rolls were unwound and converted into a three-ply basesheet for subsequent application of the various softening compositions.

- the finished basis weight of the three-ply basesheet was about 22.7 pounds per 2880

- the softening composition was simultaneously appied to both surfaces of the three-ply basesheet by rotogravure printing.

- the gravure rolls were electronically engraved, chrome over copper rolls supplied by Southern Graphics Systems, located at Louisville, Ky.

- the rolls had a line screen of 360 cells per lineal inch and a volume of 1.5 Billion Cubic Microns (BCM) per square inch of roll surface. Typical cell dimensions for this roll were 65 microns in length, 110 microns in width, and 13 microns in depth.

- the rubber backing offset applicator rolls were a 75 Shore A durometer cast polyurethane supplied by American Roller Company, located at Union Grove, Wis.

- the process was set up to a condition having 0.375 inch interference between the gravure rolls and the rubber backing rolls and 0.003 inch clearance between the facing rubber backing rolls.

- the simultaneous offset/offset gravure printer was run at a speed of 2000 feet per minute. This process yielded a solids add-on level of about 1.0 weight percent based on the dry weight of the finished tissue product. (0.5 dry weight percent on each side of the product.

- Single-ply, three-layered uncreped throughdried bath tissue basesheets were made generally in accordance with the following procedure using eucalyptus pulp fibers for the outer layers and softwood pulp fibers for the inner layer.

- a quaternary ammonium oleylimidazoline softening agent (Prosoft TQ-1003 from Hercules, Inc.) was added at a dosage of 4.1 kg/Mton of active chemical per metric ton of pulp fiber to the eucalyptus furnish. After allowing 20 minutes of mixing time, the furnish was dewatered using a belt press to approximately 32% consistency.

- the filtrate from the dewatering process was either sewered or used as pulper make-up water for subsequent pulp fiber batches but not sent forward in the stock preparation or tissue making process.

- the thickened pulp fiber containing the debonder was subsequently redispersed in water and used as the outer layer furnishes in the tissue making process.

- the softwood pulp fibers were pulped for 30 minutes at 4 percent consistency and diluted to about 3.2 percent consistency after pulping, while the debonded eucalyptus pulp fibers were diluted to about 2 percent consistency.

- the overall layered tissue sheet weight was split about 30%/about 40%/about 30% among the eucalyptus/refined softwood/eucalyptus pulp fiber layers.

- the center layer was refined to levels required to achieve target strength values, while the outer layers provided the surface softness and bulk.

- a three-layered headbox was used to form the wet tissue sheet with the refined northern softwood kraft stock in the two center layers of the head box to produce a single center layer for the three-layered tissue product described.

- Turbulence-generating inserts recessed about 3 inches (75 millimeters) from the slice and layer dividers extending about 1 inch (25.4 millimeters) beyond the slice were employed.

- the net slice opening was about 0.9 inch (23 millimeters) and water flows in all four headbox layers were comparable.

- the consistency of the stock fed to the headbox was about 0.09 weight percent.

- the resulting three-layered tissue sheet was formed on a twin wire, suction form roll, former with forming fabrics being Lindsay 2164 and Asten 867A fabrics, respectively.

- the speed of the forming fabrics was 11.9 meters per second.

- the newly-formed tissue sheet was then dewatered to a consistency of about 20 to about 27 percent using vacuum suction from below the forming fabric before being transferred to the transfer fabric, which was traveling at about 9.1 meters per second (30% rush transfer).

- the transfer fabric was an Appleton Wire T807-1.

- a vacuum shoe pulling about 6-15 inches (150-380 millimeters) of mercury vacuum was used to transfer the tissue sheet to the transfer fabric.

- the tissue sheet was then transferred to a throughdrying fabric (Lindsay Wire T1205-1).

- the throughdrying fabric was traveling at a speed of about 9.1 meters per second.

- the tissue sheet was carried over a Honeycomb throughdryer operating at a temperature of about 350° F. (175° C.) and dried to final dryness of about 94-98 percent consistency.

- the resulting uncreped tissue sheet was then wound into a parent roll.

- the parent roll was then unwound and the tissue sheet was calendered twice.

- the tissue sheet was calendered between a steel roll and a rubber covered roll having a 4 P&J hardness.

- the calender loading was about 90 pounds per lineal inch (pli).

- the tissue sheet was calendered between a steel roll and a rubber covered roll having a 40 P&J hardness.

- the calender loading was about 140 pli.

- the thickness of the rubber covers was about 0.725 inch (1.84 centimeters).

- the calendered single-ply tissue sheet was then fed into the rubber-rubber nip of the rotogravure coater to apply the softness composition to both sides of the tissue sheet.

- the gravure rolls were electronically engraved, chrome over copper rolls supplied by Specialty Systems, Inc., located at Louisville, Ky. The rolls had a line screen of 200 cells per lineal inch and a volume of 6.0 Billion Cubic Microns (BCM) per square inch of roll surface. Typical cell dimensions for this roll were 140 microns in width and 33 microns in depth using a 130 degree engraving stylus.

- the rubber backing offset applicator rolls were a 75 Shore A durometer cast polyurethane supplied by American Roller Company, located at Union Grove, Wis.

- the process was set up to a condition having 0.375 inch interference between the gravure rolls and the rubber backing rolls and 0.003 inch clearance between the facing rubber backing rolls.

- the simultaneous offset/offset gravure printer was run at a speed of 500 feet per minute using gravure roll speed adjustment (differential) to meter the polysiloxane emulsion to obtain the desired addition rate.

- the gravure roll speed differential used for this example was 500 feet per minute. This process yielded an add-on level of 2.0 weight percent total solids add-on based on the weight of the tissue.

- the tissue sheet was then converted into bath tissue rolls.

- the softness and stiffness of the tissue products were determined by a trained in-hand ranking panel, which provides a basic assessment of the softness and stiffness characteristics of a tissue product.

- the ranking panel is trained to provide holistic assessments as close as possible to those that a typical consumer might provide.

- three different assessments are made: “Softness”, “Softness-on-Face” and “Stiffness”.

- the Softness test involves evaluating the velvety, silky or fuzzy feel of the tissue sample when rubbed between the thumb and fingers.

- the Softness-on-Face test involves rubbing the tissue sample against the face, including the area between the nose and lips.

- the Stiffness test involves gathering a flat sample into one's hand and moving the sample around in the palm of the hand by drawing the fingers toward the palm and evaluating the amount of pointed, rigid or cracked edges or peaks felt. Rank data generated for each sample code by the panel are analyzed using a proportional hazards regression model. This model assumes computationally that the panelist proceeds through the ranking procedure from most of the attribute being assessed to least of the attribute.

- the softness and stiffness test results are presented in the tables below as log odds values.

- the log odds are the natural logarithm of the risk ratios that are estimated for each code from the proportional hazards regression model. Larger log odds indicate the attribute of interest is perceived with greater intensity.

- Tissue softening formulations containing various amounts of a polysiloxane (AF-2340) and glycerin were prepared.

- AF-2340 is an aqueous emulsion of an aminopolysiloxane which contains about 35 weight percent of an aminopolysiloxane fluid and formulation aids.

- the relative weight percent amounts of the polysiloxane emulsion (AF2340) and the glycerin in the various formulations are set forth in Table 1.

- Uncreped throughdried tissue product samples were prepared as described above by gravure coating the formulations onto both surfaces of a single-ply tissue basesheet. A total actives add-on of 2 dry weight percent (1 dry weight percent on each side) was evenly coated on both sides of the basesheet. The treated basesheets were then converted into bath tissue rolls and tested for softness and absorbency. The results of the testing are set forth in Table 2 and plotted in FIG. 1 .

- **“A′′ is significantly stiffer than “B′′, but only directionally stiffer than “AB′′. “AB is stiffer than “C′′, etc. Higher positive numbers correlate with greater stiffness. Larger negative numbers correlate with lower sstiffness. Since stiffness is generally undesirable for a soft product, lower numbers are more desirable.

- Tissue softening formulations were prepared based on a polysiloxane (AF-23), a fatty alkyl derivative (Tergitol 15-S-9) and glycerin.

- AF-23 is an aminopolysiloxane from Wacker Chemical and Tergitol 15-S-9 is a fatty alkyl derivative from Dow Chemical.

- the relative weight percent amounts of the polysiloxane, the fatty alkyl derivative and glycerin in the formulations are set forth in Table 3.

- Facial tissue product samples were prepared as described above by gravure coating the various formulations on both sides of a three-ply, wet-pressed, creped tissue basesheet. A total actives add-on of 1 dry weight percent (0.5 dry weight percent on each side) was evenly coated on both sides of the basesheet. The treated basesheets were then converted into folded facial tissue products and tested for softness and absorbency. The test results are set forth in Table 4.

- Tissue softening formulations containing various amounts of a polysiloxane (AF-2340), a fatty alkyl derivative (Tergitol 15-S-9) and glycerin were prepared.

- AF-2340 is an aqueous emulsion of an aminopolysiloxane which contains about 35 weight percent of an aminopolysiloxane fluid (AF-23) and formulation aids.

- the amounts of the polysiloxane, the fatty alkyl derivative and glycerin in the formulations are set forth in Table 5.

- Tissue samples were prepared as described above by gravure coating the formulations on a 1-ply uncreped throughdried tissue basesheet.

- softness compositions of this invention containing a blend of polysiloxane, a fatty alkyl derivative and glycerin at a proper ratio can provide treated tissue products with excellent softness, handfeel, good wettability and strength.

Abstract

A softening composition, particularly useful for topical treatment of tissues, comprises a polysiloxane, a fatty alkyl derivative and glycerin. The softening composition provides good softness to the tissue and enables the tissue to retain a high degree of absorbency.

Description

- The use of polysiloxanes for treating tissues is well known in the tissue industry. Polysiloxanes provide surface softness by providing a slick feel to the tissue. Inherently, however, polysiloxanes are relatively water repellant, such that the rate of absorbency for the treated tissue is lessened. In addition, polysiloxanes are relatively expensive. Consequently there is a continual need for improved tissue softening compositions that not only provide softness, but retain a satisfactory absorbent rate and are cost effective.

- Tissue softening compositions have been discovered which cost effectively provide softness while retaining a good absorbent rate (as measured by the Wet Out Time test, hereinafter described).

- Hence, in one aspect, the invention resides in a softening composition particularly useful for topically treating tissues, the composition comprising a polysiloxane, a fatty alkyl derivative and glycerin. (For purposes herein, these three ingredients are sometimes referred to as “actives”.) Optional ingredients include formulation aids and/or skin beneficial agents. More specifically, the softening composition can contain, based on the total amount of actives in the composition, from about 5 to about 40 weight percent polysiloxane, from about 10 to about 50 weight percent of a fatty alkyl derivative, from about 20 to about 80 weight percent glycerin, and from 0 to about 10 weight percent formulation aids and/or skin beneficial agents.

- In another aspect, the invention resides in a tissue sheet containing a topically applied softening composition, said softening composition comprising, based on the total amount of actives in the composition, from about 5 to about 40 weight percent polysiloxane, from about 10 to about 50 weight percent of a fatty alkyl derivative, from about 20 to about 80 weight percent glycerin and from 0 to about 10 weight percent formulation aids and/or skin beneficial agents.

- In another aspect, the invention resides in a tissue sheet containing a topically applied softening composition, said softening composition comprising, on a weight percent basis, from about 20 to about 30 weight percent polysiloxane and from about 20 to about 40 weight percent glycerin. More specifically, the weight ratio of polysiloxane:glycerin can be from about 0.5 to about 1.4.

- The amount of the softening composition actives in the tissue can be, based on the dry weight of the tissue, from about 0.2 to about 20 weight percent, more specifically from about 0.2 to about 10 weight percent, more specifically from about 0.5 to about 5 weight percent, and still more specifically from about 1 to about 3 weight percent.

- The softening composition can be applied to the tissue sheet in the form of a neat blend, an aqueous solution or an aqueous emulsion. When applied as an aqueous solution or an aqueous emulsion, the concentration of the softening composition in the aqueous solution or aqueous emulsion can be from about 35 to about 80 weight percent, more specifically from about 40 to about 70 weight percent and still more specifically from about 45 to about 70 weight percent. Suitable methods of applying the softening composition to the sheet, either directly or indirectly, include printing or spraying.

- The Wet Out Time for tissue sheets treated with the softening compositions of this invention can be about 20 seconds or less, more specifically about 15 seconds or less, more specifically from about 3 to about 15 seconds and still more specifically from about 3 to about 10 seconds.

- The amount of polysiloxane in the softening composition, based on the total amount of actives in the composition, can be from about 5 to about 40 weight percent, more specifically from about 5 to about 30 weight percent and still more specifically from about 5 to about 20 weight percent.

- Polysiloxanes useful for purposes of this invention can have one or more pendant functional groups such as amine, quaternium, aldehyde, epoxy, hydroxy, alkoxyl, polyether and carboxylic acid and its derivatives, such as amides and esters. Particularly suitable polysiloxanes have the following general structure:

- wherein:

- “m” is from 10 to 100,000;

- “n” is from 1 to 10,000;

- “p” is from 0 to 1,000;

- “A” and “B” are independently a hydroxyl, C1 to C20 or R2;

- R1, R2 and R3 are distributed in random or block fashion;

- R1 is a C1 to C8 radical, which can be straight chain, branched or cyclic;

- R2 is a C1 to C8 radical, which can be straight chain, branched or cyclic, or of the structure:

- wherein

- R4 and R5 are independently a C2 to C8 alkylene diradical, which can be straight chain or branched, substituted, or unsubstituted;

- X is an oxygen or N—R8;

- R6, R7 and R8 are independently hydrogen, a substituted or unsubstituted C1 or C2, a substituted or unsubstituted straight chain or branched or cyclic C3 to C20 alky radical, or an acyl radical, such as an acetyl radical; and

- “s” is 0 or 1;

- R3 is of the structure: R9—Y—[C2H4O]r—[C3H6O]q—R10

- wherein

- Y is an oxygen or N—R11;

- R9 is a C2 to C8 alkylene diradical, which can be straight chain or branched, substituted or unsubstituted;

- R10 and R11 are independently hydrogen, a substituted or unsubstituted C1 or C2, a substituted or unsubstituted, straight chain or branched or cyclic C3 to C20 alkyl radical;

- “r” is from 1 to 100,000; and

- “q” is from 0 to 100,000.

- When R2═R1, “A” and “B” can also be a nitrogen quarternium.

- Examples of suitable commercially available polysiloxanes include AF-2340, AF-2130, AF-23, HAF-1130, EAF-3000, EAF-340, EAF-15, AF-2740, WR-1100, WR-1300 and Wetsoft CTW from Kelmar/Wacker; DC-8822, DC-8566, DC-8211, DC-SF8417, DC-2-8630, DC-NSF, DC-8413, DC-SSF, DC-8166 from Dow Corning; SF-69, SF-99 SF-1023 from GE Silicones and Tegopren 6924, Tegopren 7990, Tego IS4111 from Goldschmidt/Degussa.

- The amount of fatty alkyl derivative in the softening composition, based on the total amount of actives in the composition, can be from about 10 to about 50 weight percent, more specifically from about 20 to about 50 weight percent and still more specifically from about 30 to about 50 weight percent.

- Fatty alkyl derivatives particularly suitable for purposes of this invention can have the following general structure:

-

R14-G - wherein:

- R14 is a C8 to C40 alkyl radical, which can be substituted or unsubstituted, primary, secondary or tertiary; straight chain, branched or cyclic; and

- “G” is hydroxy, amine, sulfonate, sulfate, phosphate, acid or acid derivative, or -Q-[C2H4O ]l—[C3H6O]j—[CtH2tO]v—R13 radical;

- wherein

- “Q” is an oxygen radical, an NH radical or N—[C2H4O}l—[C3H6O]j—[CtH2tO]v—R13 radical;

- R13 is a hydrogen, a substituted or unsubstituted C1 to C6 alkyl radical, a straight chain or branched C1 to C6 alkyl radical, or a cyclic C1 to C6 alkyl radical;

- “i”, “j” and “v” are independently from 0 to 100,000, where the oxide moieties are distributed along the polymer backbone randomly or as blocks;

- “i+j+v” is equal to or greater than 10; and

- “t” is from 4 to 10.

- Examples of suitable fatty alkyl derivatives are 9-EO ethoxylated tridecylalcohol; Ceteth-10; Ceteth-12 (12-EO ethoxylated cetyl alcohol); Ceteth-20; Pluraface A-38, Macol CSA 20 and Macol LA 12 from BASF; Armeen 16D, Armeen 18D, Armeen HTD, Armeen 2C, Armeen M2HT, Armeeh 380, Ethomeen 18/15 Armid O, Witconate 90, Witconate AOK, and Witcolate C from Akzo Nobel and Tergitol 15-S-9, Tergitol 15-S-7, Tergitol 15-S-12, Tergitol TMN-6, Tergitol TMN-10, Tergitol XH, Tergitol XDLW, and Tergitol RW-50 from Dow Chemical.

- The amount of glycerin in the softening composition can be, based on the total amount of actives in the composition, from about 20 to about 80 weight percent, more specifically from about 25 to about 80 weight percent, more specifically from about 30 to about 80 weight percent and still more specifically from about 40 to about 70 weight percent.

- Suitable formulation aids include, without limitation, emulsifiers, co-solvent, anti-foaming agents and preservatives. Suitable skin beneficial agents include, without limitation, aloe, vitamin-E, chamomile and α-hydroxy acids.

- The “Wet Out Time” of a tissue sheet treated in accordance with the present invention is determined by cutting 20 sheets of the tissue sheet sample into 2.5 inch squares. The number of sheets of the tissue sheet sample used in the test is independent of the number of plies per sheet of the tissue sheet sample. The 20 square sheets of the tissue sheet sample are stacked together and stapled at each corner to form a pad of the tissue sheet sample. The pad of the tissue sheet sample is held close to the surface of a constant temperature distilled water bath (23° C.±2° C.), which is the appropriate size and depth to ensure the saturated pad of the tissue sheet sample does not contact the bottom of the water bath container and the top surface of the distilled water of the water bath at the same time, and dropped flat onto the surface of the distilled water, with staple points on the pad of the tissue sheet sample facing down. The time necessary for the pad of the tissue sheet sample to become completely saturated, measured in seconds, is the Wet Out Time for the tissue sheet sample and represents the absorbent rate of the tissue sheet sample. Increases in the Wet Out Time represent a decrease in absorbent rate of the tissue sheet sample.

- For purposes herein, the term “tissue” means a paper sheet having a bulk of about 2 cm3 or greater/ gram, more specifically about 2.5 cm3 or greater/ gram and still more specifically about 3 cm3 or greater/gram. Such sheets are particularly useful for facial tissue, bath tissue and paper towels and can be made by any method well known to those skilled in the tissue arts. The bulk is calculated as the quotient of the caliper (hereinafter defined), expressed in microns, divided by the basis weight, expressed in grams per square meter. The resulting bulk is expressed as cubic centimeters per gram. The term “caliper” as used herein is the thickness of a single tissue sheet, and may either be measured as the thickness of a single tissue sheet or as the thickness of a stack of ten tissue sheets and dividing the ten tissue sheet thickness by ten, where each sheet within the stack is placed with the same side up. Caliper is expressed in microns and can be measured in accordance with TAPPI test methods T402 “Standard Conditioning and Testing Atmosphere For Paper, Board, Pulp Handsheets and Related Products” and T411 om-89 “Thickness (caliper) of Paper, Paperboard, and Combined Board” optionally with

Note 3 for stacked tissue sheets. The micrometer used for carrying out T411 om-89 is a Bulk Micrometer (TMI Model 49-72-00, Amityville, N.Y.) or equivalent having an anvil diameter of 4 1/16 inches (103.2 millimeters) and an anvil pressure of 220 grams/square inch (3.3 g kilo Pascals). - As used herein, the term “dry” weight percent in reference to a composition or tissue sheet containing a composition means that the amount of free water or other volatile components in the composition or tissue product are ignored. Stated differently, the “dry” weight percent is intended to represent the amount of “active components” in the composition. Therefore, for tissue sheets, all recited dry weight percent amounts refer to tissue sheets that have been aged for at least three (3) weeks and therefore have equilibrated with ambient conditions. The dry weight percent amounts can be determined by chemical extraction and analysis of the extract or, if the conditioned basis weight of the tissue sheet prior to treatment is known, by subtracting the conditioned basis weight of the untreated tissue from the conditioned basis weight of the treated tissue and dividing the difference by the conditioned basis weight of the treated tissue and multiplying by 100.

- As used herein, the “geometric mean tensile strength” (GMT) is the square root of the product of the dry machine direction tensile strength multiplied by the dry cross-machine direction tensile strength and is expressed as grams per 3 inches of sample width. The machine direction tensile strength is the peak load per 3 inches of sample width when a sample is pulled to rupture in the machine direction. Similarly, the cross-machine direction (CD) tensile strength is the peak load per 3 inches of sample width when a sample is pulled to rupture in the cross-machine direction. More specifically, samples for tensile strength testing are prepared by cutting a 3 inches (76.2 mm) wide by 5 inches (127 mm) long strip in either the machine direction (MD) or cross-machine direction (CD) orientation using a JDC Precision Sample Cutter (Thwing-Albert Instrument Company, Philadelphia, Pa., Model No. JDC 3-10, Serial No. 37333). The instrument used for measuring tensile strengths is an MTS Systems Sintech 11S, Serial No. 6233. The data acquisition software is MTS TestWorks® for Windows Ver. 3.10 (MTS Systems Corp., Research Triangle Park, N.C.). The load cell is selected from either a 50 Newton or 100 Newton maximum, depending on the strength of the sample being tested, such that the majority of peak load values fall between 10-90% of the load cell's full scale value. The gauge length between jaws is 4±0.04 inches (101.6±1 mm). The jaws are operated using pneumatic-action and are rubber coated. The minimum grip face width is 3 inches (76.2 mm), and the approximate height of a jaw is 0.5 inches (12.7 mm). The crosshead speed is 10±0.4 inches/min (254±1 mm/min), and the break sensitivity is set at 65%. The sample is placed in the jaws of the instrument, centered both vertically and horizontally. The test is then started and ends when the specimen breaks. The peak load is recorded as either the “MD tensile strength” or the “CD tensile strength” of the specimen depending on direction of the sample being tested. At least six (6) representative specimens are tested for each product or sheet, taken “as is”, and the arithmetic average of all individual specimen tests is either the MD or CD tensile strength for the product or sheet.

- The geometric mean tensile strength of the products of this invention can be, without limitation, from about 600 to about 1200 grams per 3 inches, more particularly from about 700 to about 1000 grams per 3 inches and still more specifically from about 700 to about 900 grams per 3 inches.

- In the interests of brevity and conciseness, any ranges of values set forth in this specification are to be construed as written description support for claims reciting any sub-ranges having endpoints which are whole number values within the specified range in question. By way of a hypothetical illustrative example, a disclosure in this specification of a range of from 1 to 5 shall be considered to support claims to any of the following sub-ranges: 1-4; 1-3; 1-2; 2-5; 2-4; 2-3; 3-5; 3-4 and 4-5.

-

FIG. 1 is a plot of the results of Example 1 from Table 2, illustrating the softness as a function of the glycerin percentage in the formulation containing polysiloxane and glycerin. As shown, softness peaks at about 35 weight percent glycerin and then falls off significantly as the percentage of glycerin is increased. -

FIG. 2 is a plot of the results of Example 3 from Table 6, illustrating the softness as a function of strength for various glycerin amounts in the formulation containing polysiloxane, fatty alkyl derivative and glycerin. As shown, softness peaks at about 33 weight percent glycerin. - For purposes of the following examples, tissue basesheets for use in accordance with this invention were either wet-pressed creped tissue sheets or uncreped throughdried tissue sheets. The wet-pressed tissue sheets were converted into three-ply facial tissue treated products and the uncreped throughdried tissue sheets were converted into single-ply bath tissue treated products for testing. After the tissue products were made, they were tested for geometric mean tensile strength, wettability (Wet Out Time, described above) and softness. The tissue sheets were made as described below.

- In general, these tissue basesheets were produced using a conventional wet-pressed tissue making process well known in the art. More particularly, an aqueous suspension of papermaking fibers was issued from a layered headbox onto a forming fabric. The furnish consisted of 70 weight percent hardwood (eucalyptus) fibers and 30 weight percent softwood fibers. A vacuum box beneath forming fabric was adapted to remove water from the fiber furnish to assist in forming a web. The newly formed web was transferred to a felt with aid of a pick up roll. While supported by the felt, the tissue web was lightly pressed onto the surface of a Yankee dryer using a press roll. The dried web was creped from the surface of the Yankee dryer and the resulting single-ply tissue basesheet was wound onto a parent roll. Thereafter, the basesheets from three like parent rolls were unwound and converted into a three-ply basesheet for subsequent application of the various softening compositions. The finished basis weight of the three-ply basesheet was about 22.7 pounds per 2880 square feet.

- The softening composition was simultaneously appied to both surfaces of the three-ply basesheet by rotogravure printing. The gravure rolls were electronically engraved, chrome over copper rolls supplied by Southern Graphics Systems, located at Louisville, Ky. The rolls had a line screen of 360 cells per lineal inch and a volume of 1.5 Billion Cubic Microns (BCM) per square inch of roll surface. Typical cell dimensions for this roll were 65 microns in length, 110 microns in width, and 13 microns in depth. The rubber backing offset applicator rolls were a 75 Shore A durometer cast polyurethane supplied by American Roller Company, located at Union Grove, Wis. The process was set up to a condition having 0.375 inch interference between the gravure rolls and the rubber backing rolls and 0.003 inch clearance between the facing rubber backing rolls. The simultaneous offset/offset gravure printer was run at a speed of 2000 feet per minute. This process yielded a solids add-on level of about 1.0 weight percent based on the dry weight of the finished tissue product. (0.5 dry weight percent on each side of the product.

- Single-ply, three-layered uncreped throughdried bath tissue basesheets were made generally in accordance with the following procedure using eucalyptus pulp fibers for the outer layers and softwood pulp fibers for the inner layer. Prior to pulping, a quaternary ammonium oleylimidazoline softening agent (Prosoft TQ-1003 from Hercules, Inc.) was added at a dosage of 4.1 kg/Mton of active chemical per metric ton of pulp fiber to the eucalyptus furnish. After allowing 20 minutes of mixing time, the furnish was dewatered using a belt press to approximately 32% consistency. The filtrate from the dewatering process was either sewered or used as pulper make-up water for subsequent pulp fiber batches but not sent forward in the stock preparation or tissue making process. The thickened pulp fiber containing the debonder was subsequently redispersed in water and used as the outer layer furnishes in the tissue making process. The softwood pulp fibers were pulped for 30 minutes at 4 percent consistency and diluted to about 3.2 percent consistency after pulping, while the debonded eucalyptus pulp fibers were diluted to about 2 percent consistency. The overall layered tissue sheet weight was split about 30%/about 40%/about 30% among the eucalyptus/refined softwood/eucalyptus pulp fiber layers. The center layer was refined to levels required to achieve target strength values, while the outer layers provided the surface softness and bulk.

- A three-layered headbox was used to form the wet tissue sheet with the refined northern softwood kraft stock in the two center layers of the head box to produce a single center layer for the three-layered tissue product described. Turbulence-generating inserts recessed about 3 inches (75 millimeters) from the slice and layer dividers extending about 1 inch (25.4 millimeters) beyond the slice were employed. The net slice opening was about 0.9 inch (23 millimeters) and water flows in all four headbox layers were comparable. The consistency of the stock fed to the headbox was about 0.09 weight percent. The resulting three-layered tissue sheet was formed on a twin wire, suction form roll, former with forming fabrics being Lindsay 2164 and Asten 867A fabrics, respectively. The speed of the forming fabrics was 11.9 meters per second. The newly-formed tissue sheet was then dewatered to a consistency of about 20 to about 27 percent using vacuum suction from below the forming fabric before being transferred to the transfer fabric, which was traveling at about 9.1 meters per second (30% rush transfer). The transfer fabric was an Appleton Wire T807-1. A vacuum shoe pulling about 6-15 inches (150-380 millimeters) of mercury vacuum was used to transfer the tissue sheet to the transfer fabric. The tissue sheet was then transferred to a throughdrying fabric (Lindsay Wire T1205-1). The throughdrying fabric was traveling at a speed of about 9.1 meters per second. The tissue sheet was carried over a Honeycomb throughdryer operating at a temperature of about 350° F. (175° C.) and dried to final dryness of about 94-98 percent consistency. The resulting uncreped tissue sheet was then wound into a parent roll.

- The parent roll was then unwound and the tissue sheet was calendered twice. At the first station the tissue sheet was calendered between a steel roll and a rubber covered roll having a 4 P&J hardness. The calender loading was about 90 pounds per lineal inch (pli). At the second calendering station, the tissue sheet was calendered between a steel roll and a rubber covered roll having a 40 P&J hardness. The calender loading was about 140 pli. The thickness of the rubber covers was about 0.725 inch (1.84 centimeters).

- The calendered single-ply tissue sheet was then fed into the rubber-rubber nip of the rotogravure coater to apply the softness composition to both sides of the tissue sheet. The gravure rolls were electronically engraved, chrome over copper rolls supplied by Specialty Systems, Inc., located at Louisville, Ky. The rolls had a line screen of 200 cells per lineal inch and a volume of 6.0 Billion Cubic Microns (BCM) per square inch of roll surface. Typical cell dimensions for this roll were 140 microns in width and 33 microns in depth using a 130 degree engraving stylus. The rubber backing offset applicator rolls were a 75 Shore A durometer cast polyurethane supplied by American Roller Company, located at Union Grove, Wis. The process was set up to a condition having 0.375 inch interference between the gravure rolls and the rubber backing rolls and 0.003 inch clearance between the facing rubber backing rolls. The simultaneous offset/offset gravure printer was run at a speed of 500 feet per minute using gravure roll speed adjustment (differential) to meter the polysiloxane emulsion to obtain the desired addition rate. The gravure roll speed differential used for this example was 500 feet per minute. This process yielded an add-on level of 2.0 weight percent total solids add-on based on the weight of the tissue. The tissue sheet was then converted into bath tissue rolls.

- The softness and stiffness of the tissue products were determined by a trained in-hand ranking panel, which provides a basic assessment of the softness and stiffness characteristics of a tissue product. The ranking panel is trained to provide holistic assessments as close as possible to those that a typical consumer might provide. In carrying out the test for the three-ply tissue products, three different assessments are made: “Softness”, “Softness-on-Face” and “Stiffness”. The Softness test involves evaluating the velvety, silky or fuzzy feel of the tissue sample when rubbed between the thumb and fingers. The Softness-on-Face test involves rubbing the tissue sample against the face, including the area between the nose and lips. The Stiffness test involves gathering a flat sample into one's hand and moving the sample around in the palm of the hand by drawing the fingers toward the palm and evaluating the amount of pointed, rigid or cracked edges or peaks felt. Rank data generated for each sample code by the panel are analyzed using a proportional hazards regression model. This model assumes computationally that the panelist proceeds through the ranking procedure from most of the attribute being assessed to least of the attribute. The softness and stiffness test results are presented in the tables below as log odds values. The log odds are the natural logarithm of the risk ratios that are estimated for each code from the proportional hazards regression model. Larger log odds indicate the attribute of interest is perceived with greater intensity.

- Tissue softening formulations containing various amounts of a polysiloxane (AF-2340) and glycerin were prepared. AF-2340 is an aqueous emulsion of an aminopolysiloxane which contains about 35 weight percent of an aminopolysiloxane fluid and formulation aids. The relative weight percent amounts of the polysiloxane emulsion (AF2340) and the glycerin in the various formulations are set forth in Table 1. Uncreped throughdried tissue product samples were prepared as described above by gravure coating the formulations onto both surfaces of a single-ply tissue basesheet. A total actives add-on of 2 dry weight percent (1 dry weight percent on each side) was evenly coated on both sides of the basesheet. The treated basesheets were then converted into bath tissue rolls and tested for softness and absorbency. The results of the testing are set forth in Table 2 and plotted in

FIG. 1 . -

TABLE 1 Polysiloxane emulison (AF2340) Glycerin (weight (weight Water and other formulation Formulation percent) percent) aids balance to 100% 1 100% 0% ″ 2 80% 20% ″ 3 60% 40% ″ 4 40% 60% ″ 5 20% 80% ″ 6 0% 80% ″ -

TABLE 2 GMT WOT Softness* Stiffness** Formulation (grams) (seconds) (Log odds) (Log odds) 1 713 19.9 BC (0.0000) CD (0.0000) 2 701 25.6 AB (0.2510) D (0.1421) 3 695 26.0 AB (0.2709) DE (0.2677) 4 714 22.6 C (−0.1609) C (0.2630) 5 744 24.8 D (−0.6376) B (1.0242) 6 760 4.0 E (−3.7391) A (2.4454) *“A″ is significantly softer than “B″, but only directionally softer than “AB″. “AB″ is softer than “C″, etc. Higher positive numbers correlate with greater softness. Larger negative numbers correlate with lower soffness. Hence higher numbers are more desirable. **“A″ is significantly stiffer than “B″, but only directionally stiffer than “AB″. “AB is stiffer than “C″, etc. Higher positive numbers correlate with greater stiffness. Larger negative numbers correlate with lower sstiffness. Since stiffness is generally undesirable for a soft product, lower numbers are more desirable. - The results, as further illustrated in

FIG. 1 , show that AF-2340 polysilxane is an excellent tissue softening chemical, while glycerin is significantly less effective. Furthermore, Formulation 2 (containing 20 weight percent glycerin and 80 weight percent polysiloxane emulsion (28 dry weight percent polysiloxane)) and Formulation 3 (containing 40 weight percent glycerin and 60 weight percent polysiloxane emulsion (21 dry weight percent polysiloxane)) unexpectedly provided the treated tissues with softer handfeel than those treated by either glycerin or polysiloxane alone, illustrating a synergistic effect when the polysiloxane:glycerin weight ratio is from about 0.5 to 1.4 and the absolute level of glycerin is from about 20 to about 40 weight percent. - Tissue softening formulations were prepared based on a polysiloxane (AF-23), a fatty alkyl derivative (Tergitol 15-S-9) and glycerin. AF-23 is an aminopolysiloxane from Wacker Chemical and Tergitol 15-S-9 is a fatty alkyl derivative from Dow Chemical. The relative weight percent amounts of the polysiloxane, the fatty alkyl derivative and glycerin in the formulations are set forth in Table 3. (Note that the weight percentage amounts are for the formulation, which contains water, as opposed to the relative amounts of the actives that will ultimately be present on the treated tissue.) Facial tissue product samples were prepared as described above by gravure coating the various formulations on both sides of a three-ply, wet-pressed, creped tissue basesheet. A total actives add-on of 1 dry weight percent (0.5 dry weight percent on each side) was evenly coated on both sides of the basesheet. The treated basesheets were then converted into folded facial tissue products and tested for softness and absorbency. The test results are set forth in Table 4.

-

TABLE 3 Fatty Alkyl Polysiloxane Derivative Glycerin Water and other (weight (weight (weight formulation aids Formulation percent) percent) percent) balance to 100% 1 (Control) 35% 0% 0% ″ 2 (Invention) 6% 18% 20% ″ 3 (Invention) 9% 15% 20% ″ -

TABLE 4 Softness WOT on Face Softness Stiffness Formulation GMT (grams) (seconds) (Log odds) (Log odds) (Log odds) 1 (control) 895 14.7 B E (−1.4762) BCD (0.0754) (−0.6321) 2 (Invention) 969 6.2 A (0.1515) CD (−0.4977) D (−.00354) 3 (Invention) 958 8.7 A (0.0928) A (0.8301) D (−0.0953) - The results illustrate that although AF-2340 polysilxane is an excellent tissue softening chemical, the compositions of this invention (

Formulations 2 and 3) are more effective while also providing improved wettability (lower Wet Out Times). - Tissue softening formulations containing various amounts of a polysiloxane (AF-2340), a fatty alkyl derivative (Tergitol 15-S-9) and glycerin were prepared. AF-2340 is an aqueous emulsion of an aminopolysiloxane which contains about 35 weight percent of an aminopolysiloxane fluid (AF-23) and formulation aids. The amounts of the polysiloxane, the fatty alkyl derivative and glycerin in the formulations are set forth in Table 5. Tissue samples were prepared as described above by gravure coating the formulations on a 1-ply uncreped throughdried tissue basesheet. A total actives add-on of 2 dry weight percent (1 dry weight percent on each side) was evenly coated on both sides of the basesheet. The treated basesheets were then converted into rolled bath tissue and tested for softness and absorbency. The test results are set forth in Table 6 and further illustrated in

FIG. 2 . -

TABLE 5 Fatty Alkyl Polysiloxane Derivative Glycerin Water and other (weight (weight (weight formulation aids Formulation percent) percent) percent) balance to 100% 1 (Control) 7.5% 22.5% 0% ″ 2 (Invention) 6.25% 18.7% 16.7% ″ 3 (Invention) 5.0% 15.0% 33.3% ″ 4 (Invention) 3.8% 11.2% 50% ″ -

TABLE 6 GMT WOT Softness Stiffness Formulation (grams) (seconds) (Log odds) (Log odds) 1 (Control) 617 4.4 CD (0.5805) A (0.0000) 2 (Invention) 678 4.3 BC (0.9033) DE (−0.9016) 3 (Invention) 701 4.3 AB (1.2924) AB (−0.1403)) 4 (Invention) 740 4.8 BC (0.8915) ABCD (−0.5289) - These results further illustrate that softness compositions of this invention containing a blend of polysiloxane, a fatty alkyl derivative and glycerin at a proper ratio can provide treated tissue products with excellent softness, handfeel, good wettability and strength.

- It will be appreciated that the foregoing description and examples, given for purposes of illustration, is not to be construed as limiting the scope of the invention, which is defined by the following claims and all equivalents thereto.

Claims (21)

1. A tissue softening composition comprising, based on the total amount of actives in the composition, from about 5 to about 40 weight percent polysiloxane, from about 10 to about 50 weight percent of an fatty alkyl derivative, from about 20 to about 80 weight percent glycerin.

2. The composition of claim 1 wherein the amount of polysiloxane is from about 5 to about 30 weight percent.

3. The composition of claim 1 wherein the amount of polysiloxane is from about 5 to about 20 weight percent.

4. The composition of claim 1 wherein the amount of fatty alkyl derivative is from about 20 to about 50 weight percent.

5. The composition of claim 1 wherein the amount of fatty alkyl derivative is from about 30 to about 50 weight percent.

6. The composition of claim 1 wherein the amount of glycerin is from about 25 to about 80 weight percent.

7. The composition of claim 1 wherein the amount of glycerin is from about 30 to about 80 weight percent.

8. The composition of claim 1 wherein the amount of glycerin is from about 30 to about 70 weight percent.

9. The composition of claim 1 wherein the amount of polysiloxane is from about 5 to about 20 weight percent, the amount of fatty alkyl derivative is from about 20 to about 50 weight percent and the amount of glycerin is from about 40 to about 70 weight percent.

10. A tissue sheet containing from about 0.2 to about 20 dry weight percent, based on the dry weight of the tissue sheet, of a topically applied softening composition, said softening composition comprising, based on the total amount of actives in the composition, from about 5 to about 50 weight percent polysiloxane, from about 10 to about 50 weight percent of a fatty alkyl derivative and from about 20 to about 80 weight percent glycerin.

11. The tissue sheet of claim 10 wherein the amount of the softening composition is from about 0.5 to about 5 dry weight percent.

12. The tissue sheet of claim 10 wherein the amount of the softening composition is from about 1 to about 2 dry weight percent.

13. The tissue sheet of claim 10 having a Wet Out Time of about 20 seconds or less.

14. The tissue sheet of claim 10 having a Wet Out Time of from about 3 to about 15 seconds.

15. The tissue sheet of claim 10 having a Wet Out Time of from about 3 to about 10 seconds.

16. The tissue sheet of claim 10 wherein the amount of the softening composition is from about 1 to about 2 dry weight percent, wherein the amount of polysiloxane in the softening composition is from about 5 to about 20 weight percent, the amount of fatty alkyl derivative in the softening composition is from about 30 to about 50 weight percent and the amount of glycerin in the softening composition is from about 40 to about 70 weight percent, said tissue sheet having a Wet Out Time of from about 3 to about 10 seconds.

17. The tissue sheet of claim 16 having a geometric mean tensile strength of from about 600 to about 1200 grams per 3 inches.

18. The tissue sheet of claim 16 having a geometric mean tensile strength of from about 700 to about 1000 grams per 3 inches.

19. The tissue sheet of claim 16 having a geometric mean tensile strength of from about 700 to about 900 grams per 3 inches.

20. A tissue sheet containing a topically applied softening composition, said softening composition comprising, on a weight percent basis, from about 20 to about 30 weight percent polysiloxane and from about from about 20 to about 40 weight percent glycerin.

21. The tissue sheet of claim 20 wherein the weight ratio of polysiloxane:glycerin is from about 0.5 to about 1.4.

Priority Applications (11)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/726,588 US20080230196A1 (en) | 2007-03-22 | 2007-03-22 | Softening compositions for treating tissues which retain high rate of absorbency |

| PCT/IB2008/050247 WO2008114154A1 (en) | 2007-03-22 | 2008-01-23 | Softening compositions for treating tissues which retain a high rate of absorbency |

| MX2009009073A MX2009009073A (en) | 2007-03-22 | 2008-01-23 | Softening compositions for treating tissues which retain a high rate of absorbency. |

| AU2008227976A AU2008227976A1 (en) | 2007-03-22 | 2008-01-23 | Softening compositions for treating tissues which retain a high rate of absorbency |

| EP08702503A EP2069574A1 (en) | 2007-03-22 | 2008-01-23 | Softening compositions for treating tissues which retain a high rate of absorbency |

| JP2009554101A JP2010522279A (en) | 2007-03-22 | 2008-01-23 | Softening composition for tissue treatment that maintains high absorbency |

| KR1020097016997A KR20100014788A (en) | 2007-03-22 | 2008-01-23 | Softening compositions for treating tissues which retain a high rate of absorbency |

| ARP080100940A AR065632A1 (en) | 2007-03-22 | 2008-03-07 | A SOFTENING COMPOSITION OF TISU |

| PE2008000441A PE20081639A1 (en) | 2007-03-22 | 2008-03-07 | SOFTENING COMPOSITIONS TO TREAT TISSUES THAT MAINTAIN A HIGH ABSORBENCE RATE |

| TW097107971A TW200914683A (en) | 2007-03-22 | 2008-03-07 | Softening compositions for treating tissues which retain a high rate of absorbency |

| CL200800697A CL2008000697A1 (en) | 2007-03-22 | 2008-03-07 | SOFTENING COMPOUND FOR TISU PAPER CONTAINING (BY WEIGHT), BASED ON THE TOTAL AMOUNT OF ASSETS IN THE COMPOSITION, 5-40% POLYSYLOXANE, 10-50% FAT RENTAL DERIVATIVE, 20-80% GLYCERINE; AND LAMINA TISU CONTAINING 0.2-20% IN DRY WEIGHT, IN BA |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/726,588 US20080230196A1 (en) | 2007-03-22 | 2007-03-22 | Softening compositions for treating tissues which retain high rate of absorbency |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20080230196A1 true US20080230196A1 (en) | 2008-09-25 |

Family

ID=39643835

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/726,588 Abandoned US20080230196A1 (en) | 2007-03-22 | 2007-03-22 | Softening compositions for treating tissues which retain high rate of absorbency |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20080230196A1 (en) |

| EP (1) | EP2069574A1 (en) |

| JP (1) | JP2010522279A (en) |

| KR (1) | KR20100014788A (en) |

| AR (1) | AR065632A1 (en) |

| AU (1) | AU2008227976A1 (en) |

| CL (1) | CL2008000697A1 (en) |

| MX (1) | MX2009009073A (en) |

| PE (1) | PE20081639A1 (en) |

| TW (1) | TW200914683A (en) |

| WO (1) | WO2008114154A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20080230195A1 (en) * | 2007-03-22 | 2008-09-25 | Frederick John Lang | Tissue products containing non-fibrous polymeric surface structures and a topically-applied softening composition |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110965389A (en) | 2018-09-30 | 2020-04-07 | 埃肯有机硅(上海)有限公司 | Paper softener composition |

Citations (85)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3338992A (en) * | 1959-12-15 | 1967-08-29 | Du Pont | Process for forming non-woven filamentary structures from fiber-forming synthetic organic polymers |

| US3341394A (en) * | 1966-12-21 | 1967-09-12 | Du Pont | Sheets of randomly distributed continuous filaments |

| US3502763A (en) * | 1962-02-03 | 1970-03-24 | Freudenberg Carl Kg | Process of producing non-woven fabric fleece |

| US3502538A (en) * | 1964-08-17 | 1970-03-24 | Du Pont | Bonded nonwoven sheets with a defined distribution of bond strengths |

| US3542615A (en) * | 1967-06-16 | 1970-11-24 | Monsanto Co | Process for producing a nylon non-woven fabric |

| US3556933A (en) * | 1969-04-02 | 1971-01-19 | American Cyanamid Co | Regeneration of aged-deteriorated wet strength resins |

| US3556932A (en) * | 1965-07-12 | 1971-01-19 | American Cyanamid Co | Water-soluble,ionic,glyoxylated,vinylamide,wet-strength resin and paper made therewith |

| US3575173A (en) * | 1969-03-13 | 1971-04-20 | Personal Products Co | Flushable disposable absorbent products |

| US3585104A (en) * | 1968-07-29 | 1971-06-15 | Theodor N Kleinert | Organosolv pulping and recovery process |

| US3645992A (en) * | 1967-03-02 | 1972-02-29 | Du Pont Canada | Process for preparation of homogenous random partly crystalline copolymers of ethylene with other alpha-olefins |

| US3669822A (en) * | 1971-01-11 | 1972-06-13 | Chemed Corp | Film-tissue paper adhesive laminates |

| US3692618A (en) * | 1969-10-08 | 1972-09-19 | Metallgesellschaft Ag | Continuous filament nonwoven web |

| US3700623A (en) * | 1970-04-22 | 1972-10-24 | Hercules Inc | Reaction products of epihalohydrin and polymers of diallylamine and their use in paper |

| US3772076A (en) * | 1970-01-26 | 1973-11-13 | Hercules Inc | Reaction products of epihalohydrin and polymers of diallylamine and their use in paper |

| US3802817A (en) * | 1969-10-01 | 1974-04-09 | Asahi Chemical Ind | Apparatus for producing non-woven fleeces |

| US3849241A (en) * | 1968-12-23 | 1974-11-19 | Exxon Research Engineering Co | Non-woven mats by melt blowing |

| US3855158A (en) * | 1972-12-27 | 1974-12-17 | Monsanto Co | Resinous reaction products |

| US3879257A (en) * | 1973-04-30 | 1975-04-22 | Scott Paper Co | Absorbent unitary laminate-like fibrous webs and method for producing them |

| US3899388A (en) * | 1970-02-02 | 1975-08-12 | Monsanto Co | Treating compositions |

| US4076698A (en) * | 1956-03-01 | 1978-02-28 | E. I. Du Pont De Nemours And Company | Hydrocarbon interpolymer compositions |

| US4100324A (en) * | 1974-03-26 | 1978-07-11 | Kimberly-Clark Corporation | Nonwoven fabric and method of producing same |

| US4129528A (en) * | 1976-05-11 | 1978-12-12 | Monsanto Company | Polyamine-epihalohydrin resinous reaction products |

| US4147586A (en) * | 1974-09-14 | 1979-04-03 | Monsanto Company | Cellulosic paper containing the reaction product of a dihaloalkane alkylene diamine adduct and epihalohydrin |

| US4222921A (en) * | 1978-06-19 | 1980-09-16 | Monsanto Company | Polyamine/epihalohydrin reaction products |

| US4309510A (en) * | 1979-10-18 | 1982-01-05 | Hoechst Aktiengesellschaft | Sizing composition |

| US4329000A (en) * | 1980-08-28 | 1982-05-11 | Caterpillar Tractor Co. | Self-contained, damped ball bearing assembly |

| US4340563A (en) * | 1980-05-05 | 1982-07-20 | Kimberly-Clark Corporation | Method for forming nonwoven webs |

| US4355066A (en) * | 1980-12-08 | 1982-10-19 | The Kendall Company | Spot-bonded absorbent composite towel material having 60% or more of the surface area unbonded |

| US4375448A (en) * | 1979-12-21 | 1983-03-01 | Kimberly-Clark Corporation | Method of forming a web of air-laid dry fibers |

| US4440898A (en) * | 1982-06-17 | 1984-04-03 | Kimberly-Clark Corporation | Creping adhesives containing ethylene oxide/propylene oxide copolymers |

| US4494278A (en) * | 1977-11-08 | 1985-01-22 | Karl Kristian Kobs Kroyer | Apparatus for the production of a fibrous web |

| US4514345A (en) * | 1983-08-23 | 1985-04-30 | The Procter & Gamble Company | Method of making a foraminous member |

| US4528239A (en) * | 1983-08-23 | 1985-07-09 | The Procter & Gamble Company | Deflection member |

| US4574021A (en) * | 1983-03-03 | 1986-03-04 | Kimberly-Clark Corporation | Soft moisture resistant tissue product |

| US4594130A (en) * | 1978-11-27 | 1986-06-10 | Chang Pei Ching | Pulping of lignocellulose with aqueous alcohol and alkaline earth metal salt catalyst |

| US4599392A (en) * | 1983-06-13 | 1986-07-08 | The Dow Chemical Company | Interpolymers of ethylene and unsaturated carboxylic acids |

| US4640810A (en) * | 1984-06-12 | 1987-02-03 | Scan Web Of North America, Inc. | System for producing an air laid web |

| US5382400A (en) * | 1992-08-21 | 1995-01-17 | Kimberly-Clark Corporation | Nonwoven multicomponent polymeric fabric and method for making same |

| US5432000A (en) * | 1989-03-20 | 1995-07-11 | Weyerhaeuser Company | Binder coated discontinuous fibers with adhered particulate materials |

| US5543215A (en) * | 1992-08-17 | 1996-08-06 | Weyerhaeuser Company | Polymeric binders for binding particles to fibers |

| US5753245A (en) * | 1994-08-26 | 1998-05-19 | The Procter & Gamble Company | Personal cleansing compositions |

| US5871763A (en) * | 1997-04-24 | 1999-02-16 | Fort James Corporation | Substrate treated with lotion |

| US5885697A (en) * | 1996-12-17 | 1999-03-23 | Kimberly-Clark Worldwide, Inc. | Soft treated tissue |

| US6306408B1 (en) * | 1997-03-19 | 2001-10-23 | Sca Hygiene Products Gmbh | Composition containing humidity regulators, for tissue products |